In this tutorial, we will learn to interface MPU6050 MEMS module with Pic microcontroller. Firstly, we will see an introduction of MPU6050 such as pinout diagram, pin configuration, features, specifications. At the end, we will see how to interface the MPU6050 module with Pic microcontroller. You can use any pic microcontroller which has at least one I2C interfacing port.

MPU6050 Sensor Module Introduction

MPU6050 sensor module is a MEMS( Micro Electro-Mechanical System) module which contains an integrated circuit MPU6050 IC. This chips contains three axis gyroscope, three axis accelerometer and digital motion control processor within a single IC package. On top of that, it also contains an integrated temperature sensor. All these sensors are manufactured on the same die of MPU6050. We can use this module for velocity, acceleration, orientation, displacement and other motion related parameters measurement. Now-a-days all modern smartphones come with a built-in inertial motion sensor. MPU6050 also belongs to one of this category of sensors. This sensor provides a complete solution for any six axis motion tracking system.

One of the most important features of MPU6050 MEMS sensors is that it contains a powerful and high processing power digital motion processor (DMP). DMP performs all complex calculations internally before letting the users read data from the sensor on the I2C port. That means we do not have to perform high power calculations on the microcontroller after reading data from the MPU6050 chip.

I2C Output Interface

As discussed earlier, MPU6050 provides output data on an I2C bus. Therefore, we can use a 12C bus interface of MPU6050 to transfer a 3-axis accelerometer and 3-axis gyroscope values to a microcontroller. In other words, we can use any microcontroller which has an I2C port to read sensors’ output data. There is a specific dedicated address assigned to each parameter value in the MPU6050 I2C interface. We can use these addresses to get specific values from a sensor such as acceleration, gyro and temperature.

One of the advantages of using the I2C interface of this sensor is that we can interface multiple MPU5060 modules with a single microcontroller.

Applications

This sensor has so many applications such as in robots for self-balancing, UAVs, smart phones and it also helps the object which is attached with this sensor to get the exact position in three dimensional space. These are easily available in the market. A simple MPU 6050 sensor module is shown in figure below:

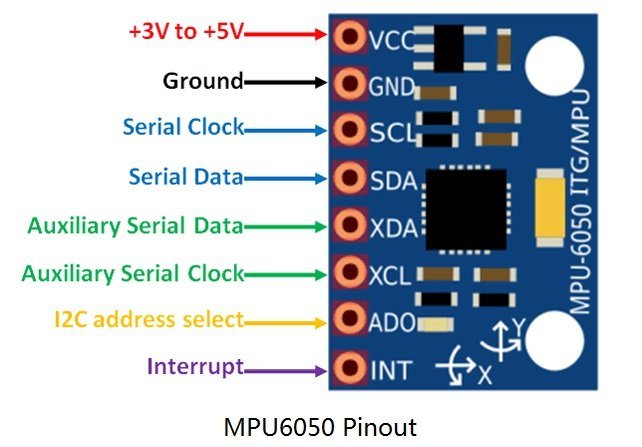

MPU6050 Pinout

The MPU6050 chip consists of 24 pins. But only 8 pins are exposed on the pinout of the module. This MEMS sensor module consists of 8 pins and these pins are used for different configurations and used to read data from the sensor.

- First one is a VCC pin that is used to power the sensor and 3 to 5 volts dc voltages are applied to power on this sensor. But usually, a 5V power source is provided directly from a microcontroller.

- The second [pin is a GND pin which is connected to the source ground and ground pin of a microcontroller.

- Pin number three is a SCL (serial clock) pin which is connected to a microcontroller SCL pin to which we want to interface MPU6050 sensor. SCL is a clock pulse pin used in I2C communication. The clock source is provided by the master device which is a microcontroller in our case.

- Fourth pin is a SDA (serial data) pin which is used to transfer data to a microcontroller. We connect SDA pin of MPU6050 with a SDA pin of a microcontroller

- Fifth one is a XDA (Auxiliary Serial Data) pin which is used to connect external I2C modules with MPU6050 such as magnetometer. But the use of this pin is completely optional.

- Sixth one is a XCL (Auxiliary clock) pin which is also connected to another 12C interface sensor to enable its pin from this sensor module.

- AD0 (Pin7) : AD0 (Address select pin) which is a 12C slave address select pin.For example, if we use more than one MPU6050 modules with a single microcontroller, this pin is used to vary the slave address for each MEMS sensor. By doing so, each MEMS sensor can be easily distinguished on an I2C bus with its unique address.

- INT(Pin8) : The INT (interrupt) pin which is an interrupt digital output pin and used to give indication to a microcontroller that the data is available to read from a MPU6050 sensor module.

The following picture shows the pinout diagram of MPU6050 MEMS module:

MPU6050 Module Circuit Diagram

The following figures show the internal circuit diagram of this module. As you can see that, the hardware used for this module is simple enough to understand. The main part of this module is a MPU6050 IC. Other than this, only a few external resistors, capacitors, a voltage regulator, power source indication LED are used.

The resistors R4 (4.7k) and R5 (4.7k) which are shown in the top right corner in the schematic diagram are the pull-up resistor required for I2C Bus. Pull-up resistors are already connected with SDA and SCL pins of MPU6050 IC. Therefore, we do not need to enable internal pull-up resistors of a microcontroller I2C port. Even if the microcontroller I2C port does not have an internal pull-up resistor, we do not need to use external pull-up resistors.

MPU6050 Sensor Module Working

MPU6050 sensor works on the principle of MEMS (micro electromechanical system) technology. Basically, this sensor module is a six DOF (degree of freedom) or six axis sensor module, therefore, it provides six outputs. From these six outputs values, three come from the gyroscope and three come from the accelerometer. Because both gyroscope and accelerometer are embedded inside a single chip.

As discussed earlier, MPU6050 sensor module provides output data on its I2C pin. Therefore, wew can use a 12C (inter integrated circuit) port of a microcontroller to read sensor output values.

The accelerometer in this chip works on the principle of piezoelectric effect. Suppose a small box with a ball inside it and the walls of this box are made with piezoelectric crystal. When we tilt this box then the ball is forced to move in the direction of inclination due to gravity. When this ball collides with the wall of the box then a small piezo electric current is produced. On the basis of this current we can determine the inclination angle and its magnitude. Similarly, the gyroscope works on the principle of Coriolis acceleration.

Whenever change in motion occurs, an electro-mechanical system of the sensor produces a respective magnitude voltage. A MUP6050 sensor IC also has an interanl 16-bit ADC which measures this voltage change. After that, the sensor stores the voltage value in a FIFO. On every write in the buffer, the interrupt (INT) pin goes high which provides a signal to a microcontroller that the data is ready to read.

How to Interface MPU6050 Module with Microcontroller

As discussed earlier, MPU6050 sensor module provides output data on its I2C pins. Therefore, it is easy to interface this sensor with any microcontroller which has at least one I2C port. A controller such as an Arduino or microcontroller can be used to read data from an MPU6050 sensor module.

Interfacing with Pic Microcontroller

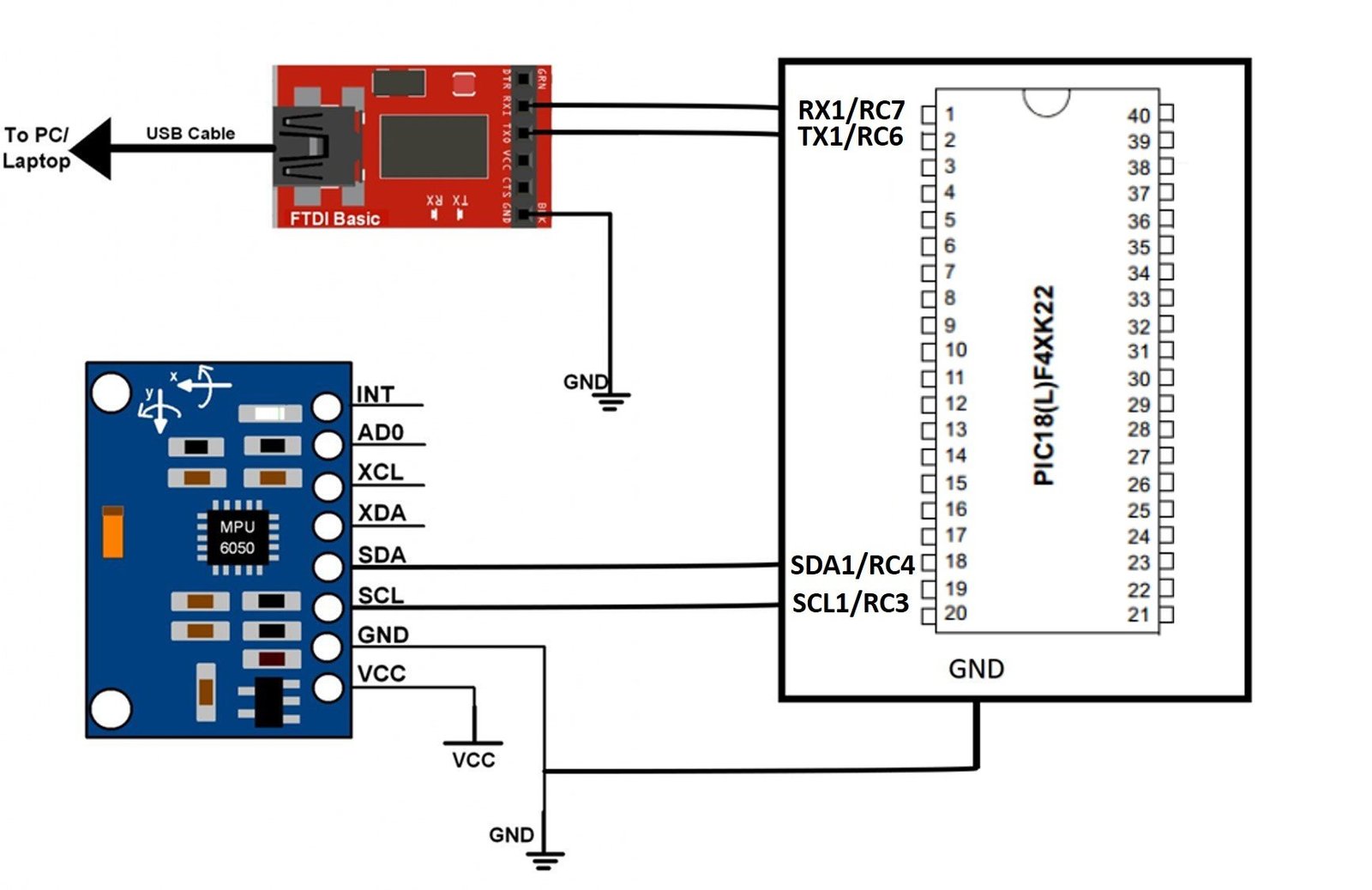

For demonstration and example, we will interface MPU6050 with a pic microcontroller. You can use any pic microcontroller. But in this tutorial, we will use a PIC18F46K22 microcontroller. The interfacing diagram of PIC18F46K22 and MPU6050 is shown below:

- Connect SDA and SCL pins of a PIC18F46K22 microcontroller with SDA and SCL pins of MPU6050 sensor module, respectively.

- Aslo, connect Vcc and GND pins of a PIC18F46K22 microcontroller with Vcc and GND pins of MPU6050 sensor module, respectively.

I2C communication drivers which we will use in the tutorial was developed in one of our last tutorial on I2C communication with pic microcontroller. You can read it here:

We will use the UART communication module of Pic microcontroller to transfer measured values of gyroscope and accelerometer to the computer. If you don’t know how to use UART communication port of pic microcontroller, you can read this post:

To get sensor data on a computer serial monitor, you need to make connection of pic microcontroller with USB to serial converter cable. If you can check this guide to know how to use an FTDI cable:

Now let’s see the code of MPU6050 for pic microcontroller.

MPU6050 Pic Microcontroller Code (MikroC)

This example code of MPU6050 for PIC18F46K22 microcontroller is written in C language with MikroC for pic compiler.

#define MPU6050_ADDRESS 0xD0

#define MPU6050_RA_XG_OFFS_TC 0x00

#define MPU6050_RA_YG_OFFS_TC 0x01

#define MPU6050_RA_ZG_OFFS_TC 0x02

#define MPU6050_RA_X_FINE_GAIN 0x03

#define MPU6050_RA_Y_FINE_GAIN 0x04

#define MPU6050_RA_Z_FINE_GAIN 0x05

#define MPU6050_RA_XA_OFFS_H 0x06

#define MPU6050_RA_XA_OFFS_L_TC 0x07

#define MPU6050_RA_YA_OFFS_H 0x08

#define MPU6050_RA_YA_OFFS_L_TC 0x09

#define MPU6050_RA_ZA_OFFS_H 0x0A

#define MPU6050_RA_ZA_OFFS_L_TC 0x0B

#define MPU6050_RA_XG_OFFS_USRH 0x13

#define MPU6050_RA_XG_OFFS_USRL 0x14

#define MPU6050_RA_YG_OFFS_USRH 0x15

#define MPU6050_RA_YG_OFFS_USRL 0x16

#define MPU6050_RA_ZG_OFFS_USRH 0x17

#define MPU6050_RA_ZG_OFFS_USRL 0x18

#define MPU6050_RA_SMPLRT_DIV 0x19

#define MPU6050_RA_CONFIG 0x1A

#define MPU6050_RA_GYRO_CONFIG 0x1B

#define MPU6050_RA_ACCEL_CONFIG 0x1C

#define MPU6050_RA_FF_THR 0x1D

#define MPU6050_RA_FF_DUR 0x1E

#define MPU6050_RA_MOT_THR 0x1F

#define MPU6050_RA_MOT_DUR 0x20

#define MPU6050_RA_ZRMOT_THR 0x21

#define MPU6050_RA_ZRMOT_DUR 0x22

#define MPU6050_RA_FIFO_EN 0x23

#define MPU6050_RA_I2C_MST_CTRL 0x24

#define MPU6050_RA_I2C_SLV0_ADDR 0x25

#define MPU6050_RA_I2C_SLV0_REG 0x26

#define MPU6050_RA_I2C_SLV0_CTRL 0x27

#define MPU6050_RA_I2C_SLV1_ADDR 0x28

#define MPU6050_RA_I2C_SLV1_REG 0x29

#define MPU6050_RA_I2C_SLV1_CTRL 0x2A

#define MPU6050_RA_I2C_SLV2_ADDR 0x2B

#define MPU6050_RA_I2C_SLV2_REG 0x2C

#define MPU6050_RA_I2C_SLV2_CTRL 0x2D

#define MPU6050_RA_I2C_SLV3_ADDR 0x2E

#define MPU6050_RA_I2C_SLV3_REG 0x2F

#define MPU6050_RA_I2C_SLV3_CTRL 0x30

#define MPU6050_RA_I2C_SLV4_ADDR 0x31

#define MPU6050_RA_I2C_SLV4_REG 0x32

#define MPU6050_RA_I2C_SLV4_DO 0x33

#define MPU6050_RA_I2C_SLV4_CTRL 0x34

#define MPU6050_RA_I2C_SLV4_DI 0x35

#define MPU6050_RA_I2C_MST_STATUS 0x36

#define MPU6050_RA_INT_PIN_CFG 0x37

#define MPU6050_RA_INT_ENABLE 0x38

#define MPU6050_RA_DMP_INT_STATUS 0x39

#define MPU6050_RA_INT_STATUS 0x3A

#define MPU6050_RA_ACCEL_XOUT_H 0x3B

#define MPU6050_RA_ACCEL_XOUT_L 0x3C

#define MPU6050_RA_ACCEL_YOUT_H 0x3D

#define MPU6050_RA_ACCEL_YOUT_L 0x3E

#define MPU6050_RA_ACCEL_ZOUT_H 0x3F

#define MPU6050_RA_ACCEL_ZOUT_L 0x40

#define MPU6050_RA_TEMP_OUT_H 0x41

#define MPU6050_RA_TEMP_OUT_L 0x42

#define MPU6050_RA_GYRO_XOUT_H 0x43

#define MPU6050_RA_GYRO_XOUT_L 0x44

#define MPU6050_RA_GYRO_YOUT_H 0x45

#define MPU6050_RA_GYRO_YOUT_L 0x46

#define MPU6050_RA_GYRO_ZOUT_H 0x47

#define MPU6050_RA_GYRO_ZOUT_L 0x48

#define MPU6050_RA_EXT_SENS_DATA_00 0x49

#define MPU6050_RA_EXT_SENS_DATA_01 0x4A

#define MPU6050_RA_EXT_SENS_DATA_02 0x4B

#define MPU6050_RA_EXT_SENS_DATA_03 0x4C

#define MPU6050_RA_EXT_SENS_DATA_04 0x4D

#define MPU6050_RA_EXT_SENS_DATA_05 0x4E

#define MPU6050_RA_EXT_SENS_DATA_06 0x4F

#define MPU6050_RA_EXT_SENS_DATA_07 0x50

#define MPU6050_RA_EXT_SENS_DATA_08 0x51

#define MPU6050_RA_EXT_SENS_DATA_09 0x52

#define MPU6050_RA_EXT_SENS_DATA_10 0x53

#define MPU6050_RA_EXT_SENS_DATA_11 0x54

#define MPU6050_RA_EXT_SENS_DATA_12 0x55

#define MPU6050_RA_EXT_SENS_DATA_13 0x56

#define MPU6050_RA_EXT_SENS_DATA_14 0x57

#define MPU6050_RA_EXT_SENS_DATA_15 0x58

#define MPU6050_RA_EXT_SENS_DATA_16 0x59

#define MPU6050_RA_EXT_SENS_DATA_17 0x5A

#define MPU6050_RA_EXT_SENS_DATA_18 0x5B

#define MPU6050_RA_EXT_SENS_DATA_19 0x5C

#define MPU6050_RA_EXT_SENS_DATA_20 0x5D

#define MPU6050_RA_EXT_SENS_DATA_21 0x5E

#define MPU6050_RA_EXT_SENS_DATA_22 0x5F

#define MPU6050_RA_EXT_SENS_DATA_23 0x60

#define MPU6050_RA_MOT_DETECT_STATUS 0x61

#define MPU6050_RA_I2C_SLV0_DO 0x63

#define MPU6050_RA_I2C_SLV1_DO 0x64

#define MPU6050_RA_I2C_SLV2_DO 0x65

#define MPU6050_RA_I2C_SLV3_DO 0x66

#define MPU6050_RA_I2C_MST_DELAY_CTRL 0x67

#define MPU6050_RA_SIGNAL_PATH_RESET 0x68

#define MPU6050_RA_MOT_DETECT_CTRL 0x69

#define MPU6050_RA_USER_CTRL 0x6A

#define MPU6050_RA_PWR_MGMT_1 0x6B

#define MPU6050_RA_PWR_MGMT_2 0x6C

#define MPU6050_RA_BANK_SEL 0x6D

#define MPU6050_RA_MEM_START_ADDR 0x6E

#define MPU6050_RA_MEM_R_W 0x6F

#define MPU6050_RA_DMP_CFG_1 0x70

#define MPU6050_RA_DMP_CFG_2 0x71

#define MPU6050_RA_FIFO_COUNTH 0x72

#define MPU6050_RA_FIFO_COUNTL 0x73

#define MPU6050_RA_FIFO_R_W 0x74

#define MPU6050_RA_WHO_AM_I 0x75

// structures

typedef struct

{

struct

{

signed int X;

signed int Y;

signed int Z;

}Accel;

signed int Temperatura;

struct

{

signed int X;

signed int Y;

signed int Z;

}Gyro;

}MPU6050;

// I2C functions

void MPU6050_Init()

{

I2C1_Init(400000);

I2C1_Start();

I2C1_Wr( MPU6050_ADDRESS );

I2C1_Wr( MPU6050_RA_PWR_MGMT_1 );

I2C1_Wr( 2 ); //Sleep OFF

I2C1_Wr( 0 );

I2C1_Stop();

I2C1_Start();

I2C1_Wr( MPU6050_ADDRESS );

I2C1_Wr( MPU6050_RA_GYRO_CONFIG );

I2C1_Wr( 0 ); //gyro_config, +-250 °/s

I2C1_Wr( 0 ); //accel_config +-2g

I2C1_Stop();

}

void MPU6050_Read( MPU6050 *Sensor )

{

I2C1_Start();

I2C1_Wr( MPU6050_ADDRESS );

I2C1_Wr( MPU6050_RA_ACCEL_XOUT_H );

I2C1_Start();

I2C1_Wr( MPU6050_ADDRESS | 1 );

Sensor->Accel.X = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Accel.Y = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Accel.Z = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Temperatura = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Gyro.X = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Gyro.Y = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(1);

Sensor->Gyro.Z = ( I2C1_Rd(1) << 8 ) | I2C1_Rd(0);

I2C1_Stop();

Sensor->Temperatura += 12421;

Sensor->Temperatura /= 340;

}

MPU6050 Sensor;

char msg[12];

void main()

{

// CMCON = 0x07;

UART1_init(9600);

MPU6050_Init();

while(1)

{

MPU6050_Read( &Sensor );

IntToStr( Sensor.Gyro.X, msg );

UART1_Write_text(msg);

IntToStr( Sensor.Gyro.Y, msg );

UART1_Write_text(msg);

IntToStr( Sensor.Gyro.Z, msg );

UART1_Write_text(msg);

IntToStr( Sensor.Accel.X, msg );

UART1_Write_text(msg);

IntToStr( Sensor.Accel.Y, msg );

UART1_Write_text(msg);

IntToStr( Sensor.Accel.Z, msg );

UART1_Write_text(msg);

Delay_ms( 500 );

}

}We have similar guides with other Microcontrollers:

Hi sir Iam trying to interface mpu6050 gyroscope sensor and I used basic code but iam facing compiling error in mpu6050 sensor and I also included mpu library and i2c library also included Arduino library manager but the code was not compiling please tell me how to resolve it thank you sir