Transformer parts, In this article I discussed about transformer parts. According to construction transformer consists of following parts.

- Steel tank

- Core

- Windings

- Conservator

- Breather

- Thermometer

- Pressure relief pipe

- Valves

- Buchholz relay

- Bushings

- Tap changing switch

- Oil gauge

- Radiator

- Cooling fans

- oil pumps

- Transformer insulation

Steel tank :

It is a main part of transformer. It is steel made box. Transformer core is placed inside this tank. Windings and other helpful devices are placed inside this tank. It is filled with insulating oil ( mineral oil ). It have usually cylindrical or cubical shape depending on transformer construction. It is coated internally and externally with colour for safety point of view. Colour coating also provide protection in case of winding connection with tank accidentally.

Core of transformer :

Core is made with laminated steel sheet in all type of transformers to provide continuous magnetic path and also to provide minimum air gap. For this purpose silicon enriched steel is used. Sometimes heat treatment is also used on steel to increase permeability of steel. hysteresis losses also decreased in core with increase in permeability. By making core laminated eddy current losses also reduced in core. Laminations of core also insulated from each other through varnish.

Two phase transformers consists of two legs and three-phase transformers are usually consists of three legs. Cores are usually circular or rectangular in shape. laminated cores tight with bolts to avoid vibration in core.

Windings :

Single phase transformer have one primary and one secondary winding. But three-phase transformer consists of three primary and three secondary windings which connects to each other with proper methods. Low voltage winding is always placed inner side of core. High voltage is placed above the low voltage winding. Both windings are electrically insulated from each other through insulation material. There is also a proper distance between two windings for movement of oil. Oil acts as a cooling agent. Because windings become hot with the flow of current in windings. To make cooling better, windings also make with many circular discs. Windings also design like a helical coils. Helical windings are used in high current transformers. According to capacity of transformer three types of coils are usually designed:

- Square wound

- continuous

- Disk wound

Coils are heat bonded with special varnish to increase mechanical strength of coils. Coils are usually concentric in core type transformers.

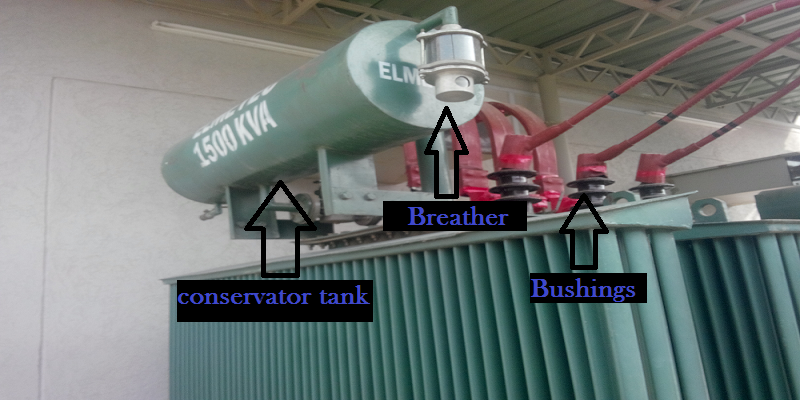

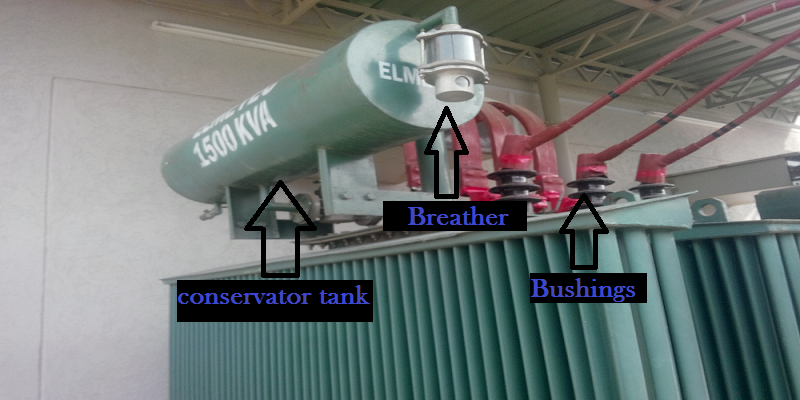

Conservator tank :

It is a small tank which used in high power transformers. It is connected above the main tank of transformer. It has cylindrical shape.Main tank and conservator tank connected to each other through a pipe. Buchholz relay is used between conservator tank and main tank in transformers having capacity more than one MVA. Conservator tank have following functions in transformer :

- It provide place for hot transformer oil to expand. It also provide oil in transformer after oil become cool.

- It also use to decrease oxidation by reducing area of oil around air.

- Oxidized oil remain in conservator tank. Mirror tube is also connected with conservator tank to read oil level in transformers. A pre marked gauge is also present in mirror tube. It is necessary to have cool oil level up to mark of gauge.

With change in temperature oil level keep decreasing and increasing. Because insulating oil have co-efficient of expansion. Whoever if large cavity is provide in upper part of main tank, contact area increases between air and oil which decrease dielectric strength of oil. To reduce this effect, we use a separate small tank through a pipe. It have less oil than main tank. This tank is called conservator tank. With the help of conservator tank, contact area reduced between oil and air. Oil also remain ineffective due to oxidation. Oxidation do not occur in main tank due to conservator tank. Hot oil move to conservator tank through pipe. Oxidation occur only in conservator tank. Due to oxidation sludge only remain in conservator tank. Sludge do not enter in main tank.

Breather :

Breather is a device which used for Breathing of transformer. Its mean air go in or out from transformer with the help of breather. Now the Question is why we need breather in transformer ? Because when hot oil expand, air go out from transformer and when oil contracts after cooling, air enters in transformer. Breather one side is connected with conservator tank. A mirror tube is placed inside breather. This mirror tube filled with calcium chloride or silica gel. When air enters in transformer, this air contain moisture. Silica gel absorb moisture and only allow dry air to enter in transformer. In this way breather with the help of silica get stop moisture contain air to pass into transformer and avoid oxidation in transformer main tank. With the time silica gel colour changes from blue to pink after absorbing specifing quantity of moisture from air. We can reuse this silica gel after warming it.

Thermometer :

Thermometer is also used in above 50KVA transformers. It is used to measure temperature of oil. In high power transformers, thermometer is also used inside windings which measure temperature of windings. Whenever temperature increase up to dangerous level, it activates alarum signal.

Dial type thermometers are usually used for activation of alarms in abnormal conditions. It give reading directly through a sensor. Whenever oil temperature increases to specific level, it provide signal to alarm circuit. Thermometer usually placed close to transformer name plate. Usually If dial type thermometer trip the transformer, when oil temperature becomes greater than 105º.

pressure relief vent :

It is a curve type mirror tube connected with main tank of transformer. It provide protection to transformer from greater pressure. Sometime greater pressure is developed inside a transformer due to decomposition of oil. It is necessary part of high power transformer. Transformer can also burst without pressure relief vent. Transformer burst above 1.01kg/cm³ pressure.

Valves :

Valves are used for filling and draining of transformer oil. It is also used for filtering and sampling. Usually three valves are available in transformer.

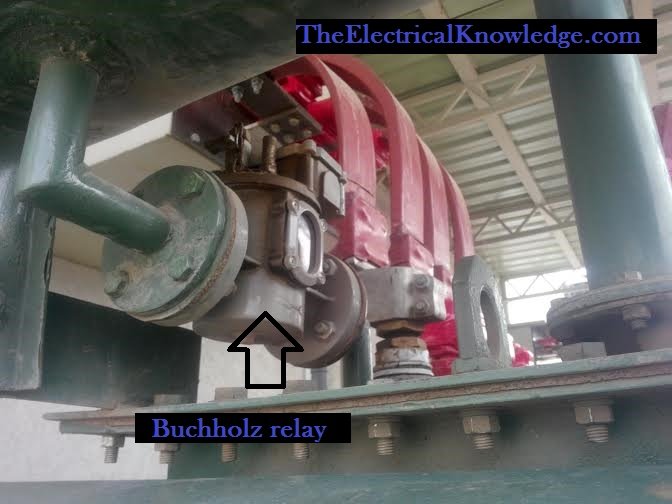

Buchholz relay

This relay is connected to a pipe between main tank and conservator tank. It is gas actuated realy. It is very important part of transformer. I will post a separate article on this. Because it is difficult to explain buchholz relay working in this article. In short buchholz relay provide protection for low oil level and high temperature.

Bushings :

Bushings are used to bring windings terminals out of tank and also use for insulation. For example porcelain, oil filled and capacitor type bushings. Arching horns are also connected to bushings to provide protection from lightning. In above 34 KV transformer, completely sealed condenser type bushings are used. In less than 25KV transformer plain bushings are used.

Tap changing switch

Tap changer switch is used to regulate secondary voltage in case of low voltage in primary side of transformer. Two type of tap changing switches are used:

- Off load switch : It is used to change winding voltage ratio. Tap changing switch are connected with high voltage side of transformer. As it name suggest off load tap changing switch used only in transformer off condition.

- On Load Switch : On load tap changer switch can be used with on load transformer.

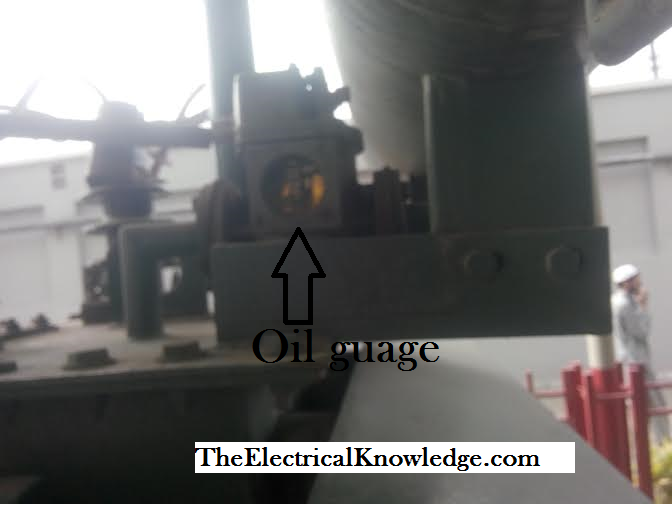

Oil gauge :

Oil gauge is used for the measurement of oil in transformer. It displays oil level. Oil gauge is usually of dial type. Pointer on dial type gauge used to measure oil level. It is used with medium level to high voltage transformers.

Radiator :

In 50KVA above transformers, radiators are used with main tank of transformer for cooling purpose. It is like a pipes or tubes. It increases the surface area of transformer. Radiator makes cooling in transformer more effective. This method of cooling is called ONAN ( oil natural air natural).

Cooling fans :

In 26MVA and above transformers, cooling fans are also used on radiator. Oil temperature gauge provide on or off signal for cooling fans. When temperature becomes greater than 75º, temperature oil gauge turn on cooling fans. This method of cooling is called ONAF ( oil natural and air forced ).

Oil pumps :

In 26 MVA above transformers oil pumps are also used along with cooling fans and radiator.oil pumps used to rotate oil in transformer. This method of cooling is called OFAF ( oil forced and air forced) .

Sir, why transformer rating in kva ?

Because transformer power factor depend on load and we don’t know exact value of load. That’s why transformer rated in KVA rather than KW

absolutly right

very good articles

sir,difference between earth and nutral?

It very explanatory

Very nice