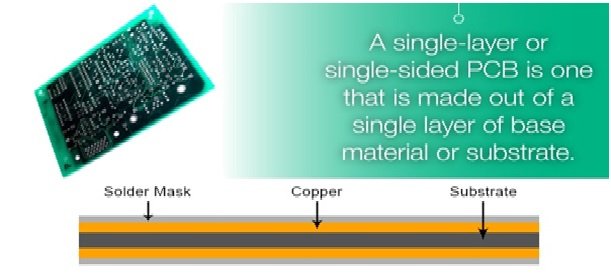

In this tutorial, we will discuss the PCB. The word PCB stands for printed circuit board, and a single layer PCB is such a type of PCB that prints on only one side. A PCB sheet that prints on one side with conductive material and on the other side with electronics components that connect electrically and mechanically. Before introducing PCB sheets, the only option was to use the point-to-point construction method to make a circuit, which was much more difficult and took more time and space. The first single sided PCB was made in 1950 and is still available on the market in bulk quantities. Nowadays, different materials are used for making single layer PCBs, such as glass fiber-reinforced epoxy resin with copper foil, paper-reinforced phenolic resin with copper foil, etc. For a simple single Layer PCB, refer to the figure below.

Figure 1 A Simple Single Layer PCB

Construction of Single Layer PCB

In the beginning, all types of PCBs were handcrafted and designed manually. Currently, we do all these designs on a computer with the help of different software programs such as ORCADS, EAGLE, PROTEL, Easy EDA, CAD, etc. First, we will explain the manual process for making the PCB board. For making a PCB board manually, first design the layout of the circuit on computer software, print this on a simple page, and then iron this page on a PCB sheet. After ironing the whole circuit on a PCB sheet, pass this PCB sheet through the etching process. Because the top layer of PCB sheet has conductive material such as copper, when we do etching with the help of ferric chloride, this layer dissolves in ferric chloride except for the printed circuit layer.

Hence, after etching, this PCB sheet is now ready to insert the electronic components. But before inserting components, we need to make holes with a drill machine. This is a manual process for making a PCB board, but now so many PCB machines are available on the market that do all this work automatically. So, in these machines, circuit layout is made with the help of software and we just need to insert the PCB sheet and components into this machine. It gives us our desired design circuit. Now, making the PCB circuit has become so much easier.

Types of Single Layer PCB

Some single layer PCBs are currently in use, and here we will explain them with respect to their manufacturing material.

Single Layer Rigid PCB

It is a type of single layer printed circuit board that has a rigid material such as fiber glass. These PCBs are inflexible and prevent the circuit from bending and breaking. Currently, these are useful in different types of devices, such as calculators, power supplies, etc. For a single layer rigid PCB, refer to the figure below.

Single Layer Flexible PCB

It is a type of single layer printed circuit board that uses a flexible material instead of a rigid one. These PCBs use plastic materials for this purpose. It has so many advantages over single layer rigid types, but its fabrication cost is so high. For a single layer flexible PCB, refer to the figure below.

Figure 3 A Single Layer Flexible PCB

Single Layer High Frequency PCB

It is the type of single layer printed circuit board that is useful for high-frequency circuits, normally in giga hertz. These PCBs are made out of Teflon or polyphenylene oxide (PPO) material. When choosing a high-frequency single layer PCB, we need to keep many aspects in mind, such as dielectric loss, thermal expansion, water absorption, etc. We can see a simple high-frequency single layer PCB in the figure below.

Figure 4 A Single Layer High Frequency PCB

Single Layer Rigid Flex PCB

It’s a type of single layer printed circuit board that has a combination of plastic and fiber glass. Both materials combine into a single layer. It has so many advantages over single layer rigid and flexible PCBs, such as reducing the weight and size of the overall PCB.

Single Layer Aluminum Backed PCB

It is a type of single layer printed circuit board that has an aluminum substrate. The design of this PCB is almost the same as that of a copper-backed PCB, but the only difference is that in these PCBs, an aluminum substrate is used instead of copper. Aluminum backing is used with thermal insulating material for transferring the heat from the insulating material to the backing.

Application of Single Layer Printed Circuit Boards

As we know the single layer printed circuit boards are very simple, but these are still in used in so much complex devices. Some of which are listed below.

| Digital Cameras | Radio and Stereo Equipment |

| Photo copy and Printer machines | Basic Digital calculators |

| Vending Machines | Switching Relays for Automotive and Power industry |

| Solid State Drives in Power Industry | Coffee Making Machine |

| Digital Microwave Oven Timer | Power Light Circuit using LEDs |

| Packing Machines in Packing Industry | Timing Circuits of Machines |

| Sensors and Products | Surveillance Machine |

| Digital and Analog Power Supply Circuit |

Advantages of Single Layer Printed Circuit Boards

Single layer PCBs have so many advantages, so which are listed below.

- Because single layer PCB is very simple therefore it is very easy to design and has lower probability to make incorrect design .

- It is less costly specially when it is ordered in bulk quantity as compared to other types of PCBs

- Because single layer PCB, only consists of a single layer therefor its drilling, soldering, de-soldering and components inserting process is very easy.

- Because its components are installed at only one side therefore it required lower jumper to compensate the circuit.

- Because its circuit is very simple therefore any one can easily understand the circuit.

- Its design circuit take a very short time to make a simple design.

- Because its components are installed at some distance form each other therefore there is less probability of short circuiting and producing noise

- Less time is required for fault tracing and repairing of this single layer PCB.

- It is more reliable and efficient as compared to other types of PCBs.

- It is easy to install.

Conclusion

In conclusion, this tutorial provides an in-depth overview of PCBs. It covers the introduction of single layer printed circuit boards along with their types, applications, and advantages to help us grasp or better understand the concepts. Hopefully, this was helpful in expanding your knowledge.

You may also like to read:

- LED PCB Board Design Guide

- Introduction to Double layer PCB – Construction and working

- Altium designer PCB designing tutorial step by step guide

- EasyEDA new desktop software for PCB and schematic design

- PCB Designing Video Tutorials

- ESP32 Bluetooth Classic with Arduino IDE: Getting Started Guide

- PC based Home Automation using Arduino

- RCWL-0516 Microwave Radar Sensor Module with ESP8266 NodeMCU

This concludes today’s article. If you face any issues or difficulties, let us know in the comment section below.