In this tutorial, we will discuss three-phase induction motors and their faults. Currently, we have been using two types of motors with respect to their supply voltages: the DC motors, which operate on DC (direct current) voltages, and the AC motors, or induction motors, which operate on AC (alternating current) voltages. But here we will only talk about three-phase induction motors, which are quite popular in domestic and industrial-level applications. These motors are highly efficient, low-cost, and small in size. It consists of two magnetic circuits that are interlinked with each other. These two main parts of the machine are the stationary part and the moving part.

Working of Induction Motor

The stationary part is the stator, and the moving part is the rotor. The power transfers from the stationary part to the moving part through electromagnetic induction; therefore, we refer to the motor as an electromechanical conversion device due to its ability to convert electrical energy into mechanical energy. The rotor is made up of insulated copper or aluminum bars and is fixed to the motor frame with the help of bearings. Similarly, the stator is made up of aluminum alloy or welded fabricated sheet and is directly fixed to the motor frame in a cylindrical shape.

When the motor powers up with a three-phase AC supply, it produces a rotating magnetic field in a stator circuit, which induces the emf in the rotator. Because the rotor short circuits through the end ring, it produces current due to induced emf. So when this current interacts with the rotating magnetic field, torque develops in the rotor in the direction of the rotating magnetic field. This is the main working principle of every induction motor. A simple three-phase induction motor is shown in Figure 1 with all its essential parts.

Figure 1 Three Phase Induction Motor with all their Essential Parts

Three Phase Induction Motor Faults and Causes

Generally, industries use two types of induction motors, such as wound rotors and squirrel cage rotors, but their faults are almost the same. Here we classify these faults into three types, but these further subdivide as well.

Types of Faults

- Electrical Faults

- Mechanical Faults

- Environmental Faults

Electrical faults

These faults further subdivide into seven types, such as:

Single Phasing Fault

This occurs when any one phase of the supply voltage is lost. This is because the requirement for normal operation of a three-phase induction motor is a three-phase voltage supply. Due to this fault, the motor could burn or heat up.

Reverse Phase Sequencing Fault

A reverse phase sequencing fault occurs when any one phase of the three-phase voltage supply is reversed, meaning the phase order of the supply voltages is swapped. Due to this fault, the direction of rotation of the motor changes.

Under and Over Supply Voltage Fault

This fault occurs when supply voltages are under or over a specific limit. The limit of three-phase AC supply voltages is 380 to 440 volts, so when supply voltages cross this limit, the motor could burn or heat up.

Overload fault

Overload occurs when a higher load connects at the output of the motor, and due to this load, the motor could heat up or experience excessive vibration.

Earth Fault

This fault occurs when any one phase of the supply voltage connects to the housing of the motor. Hence, this results in a complete short circuit of the motor. In this condition, if anyone touches this motor, he will feel a heavy shock. Besides this, the motor will take over current, which could be dangerous for an induction motor.

Inter Turn Short Circuit Fault

This type of fault occurs when two turns of the same phase or different phases short circuit each other. During this fault, the motor can suffer total damage or damage to the coils of a specific phase.

Crawling Fault

This is basically an electromechanical fault in a three-phase induction motor. This fault occurs when the motor is fully loaded with supply voltage. It does accelerate, but it runs at nearly one-seventh of its synchronous speed. This specific phenomenon of induction motors is crawling.

Mechanical Faults in Three Phase Induction Motor

Mechanical faults are such types of faults that generally occur in the internal housing of a three-phase induction motor. These faults further subdivide into three types, such as:

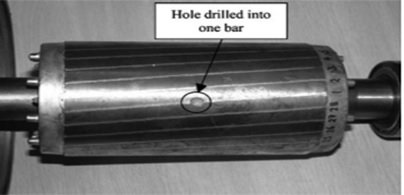

Broken Rotor Fault

The squirrel cage induction motor consists of rotor bars and a shorted end ring. If these bars suffer damage or a partial crack, then this type of fault is a rotor-broken-bar fault. There are so many reasons for this fault occurring, but mainly, it occurs due to a manufacturer defect. Because during the brazing process, non-uniform metallurgical stress may occur in rotor bars, which may lead to the rotor bars failure during the rotation of the rotor. We can see the broken rotor bar fault in the following figure:

Figure 2 Broken Rotor Bar Fault

Rotor Mass Unbalance Fault

If we concentrate on the construction of an induction motor, then we can easily know that the placement of the rotor of an induction motor is inside the stator bore and rotates coaxially with the stator. In heavy motors, it aligns at the center with the stator, and its axis of rotation is also the same as the geometrical axis of the stator. So the air gap between the inner stator and the outer rotor is the same. Similarly, if this air gap is not the same, then the situation of eccentricity will occur. In this eccentricity situation, the fault occurs due to the unbalancing of the rotor. For reference, we can see this rotor mass unbalance fault in the following figure:

Figure 3 Rotor Mass Unbalance Fault

Bearing Fault

In a three-phase induction motor, two sets of bearings are installed inside the motor housing to support the motor shaft. The main purposes of these bearings are to rotate the motor shaft freely and reduce friction. They consist of an outer and inner ring, which are known as races, and a set of rolling elements, which are known as balls. The balls are fixed on the inner and outer sides of the ring, and they reduce the friction of the shaft. To further reduce the friction, the solution is to apply lubrication to these balls. Sometimes the balls, outer, or inner ring of the bearing suffer damage due to any physical problem, and then the fault occurs. This fault is a bearing fault, and due to this fault, the motor jams totally or gets stuck. We can see the motor bearing fault in the figure below.

Figure 4 The Motor Bearing Fault

Environmental Faults in Three Phase Induction Motor

In motors, different faults could occur simultaneously, and in these faults, environmental faults are also very important. Induction motor surroundings, such as ambient temperature, moisture, etc., have an effect on the performance of induction motors. These factors reduce the performance of induction motors. Beside this, the vibration in the induction motor that could be due to any reason, such as a failed proper installation, also affects the performance of the induction motor. So during the installation of a three-phase induction motor, these factors should be kept in mind.

Conclusion

In conclusion, this tutorial provides an in-depth overview of three-phase induction motors. It covers their workings and faults. Then we discuss the faults in detail with subcategories such as electrical, mechanical, and environmental to help us better understand the concept. Hopefully, this was helpful in expanding your knowledge of three-phase induction motors.

You may also like to read:

- Three phase induction motor speed control using pic microcontroller

- Soft starter for three phase induction motor

- soft starter for single phase induction motor using pic microcontroller

- Variable Frequency Drive 3 phase Induction Motor using Pic Microcontroller

- DC Motor Control with LabVIEW and Arduino – Tutorial 3

- Control Stepper Motor with A4988 Driver Module and ESP8266 NodeMCU

- How to use PIR Motion Sensor with Raspberry Pi Pico

This concludes today’s article. If you face any issues or difficulties, let us know in the comment section below.

Thanks for the information, nice article.

thanks for the information

I have understood the faults in three phase induction motors