In this tutorial, we are going to discuss the light-emitting diode (LED). First, we will provide a basic introduction to the diode, along with its history. After this, we will discuss its construction, working principle, and I-V characteristics. Lastly, we will discuss the types of LEDs and their applications.

Introduction with History of Light-Emitting Diode

The light-emitting diode is a P-N junction diode, which consists of two leads and a semiconductor light source. It activates by applying suitable voltages across its leads. Then it emits light energy in the form of photons and determines the color of this light by the band gap of the semiconductor material. We can produce light energy through the recombination of electrons and electron holes in this device. This process is referred to as the electroluminescence process. This process was stated in the twentieth century for solid-state material. When it reaches room temperature, it emits light energy.

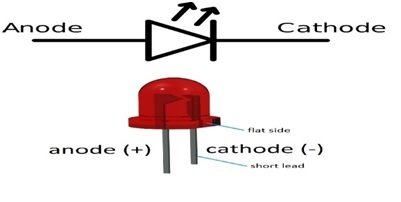

At the beginning, the infrared light-emitting diode was developed, and its light intensity was low, but it is still frequently used in a variety of consumer electronics circuits, such as remote controls. Different sizes of light-emitting diodes are available on the market, from 1mm2 to onward. One of the light-emitting diodes with an electrical symbol and a practical structure diagram is shown in Figure 1. It is also used to make LED matrixes.

Construction of Light Emitting Diode

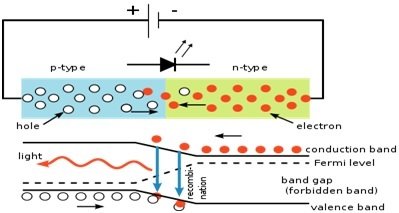

The construction of a light-emitting diode is so simple. It is made by depositing the three layers of semiconductor material on a substrate. These three semiconductor material layers make three regions, which are as follows: a P-type region, which is the top one; an active region, which is the middle one; and an N-type region, which is the bottom one. Figure 2 shows all three semiconductor material regions.

Emitting Diode

As per figure 2, the P-type region has holes. The N-type region has electrons, and the active region has both electrons and holes. In normal conditions, when there are no voltages at the anode and cathode, then all the holes and electrons are present at their places. But when we apply the voltages to this light LED, it becomes forward biased. At this stage, the holes from the p-type region and the electrons from the n-type region push up towards the active region. This is the depletion region. Because the holes have a positive charge and the electrons have a negative charge, the recombination of these opposite polarity charges produces light.

Working Principle of Light Emitting Diode

The light LED works on the same principle as a simple PN junction diode. That means when the anode connects to the positive terminal of the DC supply and the cathode connects to its negative terminal, then the PN junction is in forward bias mode. When the PN junction is in forward bias mode, then the holes in the P-type region and electrons from the N-type region recombine. During this, the conduction band forms for emitting light energy in the form of light energy photons. This whole phenomenon is an electroluminescence phenomenon, and this light energy depends upon the amount of current that the LED absorbs.

In other words, this light energy is directly proportional to the absorbing current. Which means that when it absorbs more current, the light will be high. Similarly, when it absorbs a low current, the light will be low. All the absorbing current does not convert into light energy; rather, some of it converts into heat, which LED dissipates into the external environment. This heat is electron dissipation energy. This dissipative energy also depends on the semiconductor material of the light-emitting diode. We can see the inner working diagram of this LED in Figure 3.

I-V Characteristics of Light Emitting Diode

When we apply 2 to 3 V, the light-emitting diode is in forward bias mode. It emits visible, invisible infrared, or laser light with a narrow band width. In this condition, it shows that the forward current is almost constant at the early stage. But when it is fully on, then the forward current increases constantly, as we can see in Figure 4.

The intensity of the light depends on this current. When this current is high, the intensity of the output light will be high. The voltage at which the current increases constantly is the forward voltage. We denote it as Vd in Figure 3. In reverse bias conditions, the reverse current or leakage current is almost linearly constant. But a point comes when its PN junction breaks down and reverse current increases constantly in the negative current region. The voltage at which the breakdown occurs is the breakdown voltage, and we denote it as Vbr. We can see this in Figure 4.

Types of Light Emitting Diode

We can divide LEDs into three major types according to their material.

- Traditional Inorganic LEDs

- Organic LEDs

- High-brightness LEDs

Traditional Inorganic LEDs

The traditional-type LEDs have the same shape as the traditional-type diode. These have been available on the market since 1960. These have inorganic materials; therefore, we refer to them as inorganic LEDs. Some of the most useful LEDs, which are made from semiconductor material compounds, are aluminum gallium arsenide and gallium arsenide. These are available on the market in different shapes and colors, such as surface-mounted LEDs, single-color LEDs, and flashing LEDs.

Organic LEDs

This type of LED has an organic material; therefore, we refer to them as organic LEDs. These types of LEDs show the basic idea of LEDs. The traditional inorganic LEDs use inorganic semiconductor material; therefore, these have a varying dopant level. These produce light from a PN junction; therefore, their light shows in the form of a point of light. The manufacturing of organic LEDs is done in sheets; therefore, these provide a diffuse area of light, which means they can be useful for a wide area of surface.

High Brightness LEDs

High-brightness LEDs (HBLEDs) are a type of organic LED. These are widely used for lighting purposes. Essentially, this type of LED is the same as organic LEDs. The only difference is that these have high brightness in the output light. For generating high brightness, these LEDs require a high current and high power dissipation. Therefore, these LEDs are mounted with heat sinks to remove the unwanted heat.

Applications of Light Emitting Diode

- Security alarm systems use LEDs, such as burglar alarm systems.

- Electronic calculators use LEDs to show the digital data.

- Mobile phones use LEDs as flash lights for taking pictures.

- The LEDs on traffic signals control the traffic crowds in cities.

- Their uses include lighting for homes, factories, and streets, etc.

- These are more efficient than incandescent lamps for saving energy.

- These are useful on digital computers for displaying computer data.

- A digital multimeter uses LEDs to show the current, voltage, and resistance in digital form.

- These are useful in aviation lights for aircraft warning signals.

- They are used in remote control systems such as TVs or LCDs.

- They are also used in digital watches and automotive heat lamps.

Conclusion

In conclusion, this tutorial provides an in-depth overview of Light Emitting Diodes (LEDs). It covers a basic introduction and its history. After this we discuss the construction, working principle and the types of LEDs to help us better understand the concept. At the last we discuss the applications of LEDs. Hopefully this was helpful in expanding your knowledge of LEDs.

You may also like to read:

- ESP8266 NodeMCU DS1307 RTC Real Time Clock with OLED

- Seven Segment Display Interfacing with Arduino

- STM32 Blue Pill with 4-Digit 7 Segment Display using STM32CubeIDE

- Use Push Button to Control LEDs of STM32F4 Discovery Board – Digital Input pins with HAL Driver

- ESP32 WebSocket Server using Arduino IDE – Control GPIOs and Relays

- ESP32 Save Data to Flash Permanently using Preferences Library

This concludes today’s article. If you face any issues or difficulties, let us know in the comment section below.