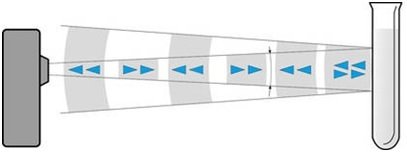

In this tutorial, we are going to discuss ultrasonic sensors. It is a sensor that measures the distance of a respective object by sending a sound wave of a specific frequency. This sound wave reflects after the collision with the respective object, and the ultra-sonic receiver receives this wave. Distance is measured by calculating the sending and receiving times of this sound wave. We can see a basic operational diagram of an ultrasonic sensor in the figure below.

The formula for measuring the distance is as follows:

Distance = Sound speed x time taken / 2

Sound travels through the air at almost 344 m/s (1129 ft/s), and we multiply this speed by the total time (sending and receiving) of the sound wave. In this formula, because we know the total time, we divide it by 2 to calculate the total distance of that respective object. Some objects are not detected by ultrasonic sensors due to their improper shape, position, and size.

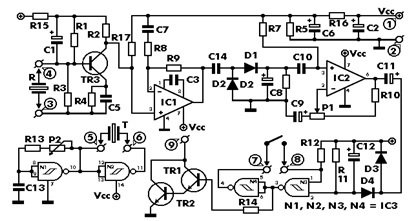

Working with Circuit Diagram of Ultrasonic Senor

In the figure below, we can see the circuit diagram of an ultrasonic sensor.

The ultrasonic sensor circuit consists of a set of ultrasonic transmitters and receivers that operate at the same frequency. When anything or an object comes into the area of the circuit, its frequency sound reflects back to the receiver and triggers the alarm. The ultrasonic sensor circuit is very sensitive, and it could be reset automatically or keep on triggering until it is reset manually.

This sensor consists of two NAND gates, which are wired as an inverter to form the multi-vibrator output for driving the transducer. It also consists of two trimmers, P1 and P2. P1 adjusts the amplification factor of inverting and non-inverting circuits, or op-amps. P2 adjusts the output frequency of the transmitter, and for good efficiency, the acquisition of the output frequency should be the same as the resonance frequency of the transducer that is in use. A transducer is useful for receiving the output signal that reflects after the collision. It amplifies this signal through the resistor TR3. We can see an ultrasonic sensor in the figure below.

Different Types of Ultrasonic Sensors

There are four major types of ultrasonic sensors currently in use:

- Ultrasonic Proximity Sensors

- Ultrasonic 2-Point Proximity Switches

- Ultrasonic Retro-reflective Sensors

- Ultrasonic Through Beam Sensors

Ultrasonic Proximity Sensors

In this ultrasonic proximity sensor, a special type of sonic transducer is used for alternate transmission and reception of sound waves. This sonic transducer emits the sonic waves the object reflects, and after this emission, this sensor switches into receive mode. The total time that passes between emitting and receiving a sound wave is inversely proportional to the distance of the object from the sensor. The digital output is only possible or sensed in the detection area. We can adjust the sensing range with the sensor’s potentiometer. We can see this sensor in the figure below.

Ultrasonic 2-Point Proximity Switches

This sensor consists of 2 points for switching; therefore, it is a 2-point proximity switch. It is almost similar to the standard sensor. The only difference is the 2-touch set-up key, and this function is the tech-in function. Its switches, Sde1 and Sde2, are easily programmable within the sensing range with the help of the built-in tech-in button. Refer to the figure below for this sensor.

Ultrasonic Retro-reflective Sensors

The operation of an ultrasonic retro-reflective sensor is similar to that of an ultrasonic proximity sensor. The only difference in this sensor is that the measurement of the distance between the sensor and the reflector is on the basis of propagation time. In this sensor, the stationary object could be useful as a reflector, and we can adjust the sensing distance (SD) by adjusting the potentiometer resistance with an ultrasonic sensor. Its working is so simple; when any object comes within the sensing distance, its propagation time changes, and by changing this propagation time, the sensor switches into active mode. This sensor also allows the detection of sound absorbents and object-deflecting sounds. We can see this sensor in the figure below.

How to Measure Speed with Ultrasonic Sensor

For measuring speed with an ultrasonic sensor, a microcontroller or any controller, such as an Arduino, is necessary to connect with this sensor. An ultrasonic sensor consists of two transducers. One acts as a speaker, which converts the electrical pulses into sound pulses and then emits them at a high frequency of almost 40 kHz. Similary, the other one acts as a microphone for receiving the sound pulses, which reflect after the collision of a specific object. Because a microcontroller or any controller attaches to an ultrasonic sensor, the timer of the controller starts to count the pulses when they transmit and stops when it receives sound waves from the microphone. Based on sending and receiving the sound pulses, the microcontroller or any controller determines the speed of that specific object.

Applications of Ultrasonic Sensor

- An ultrasonic sensor is useful in oil, chemical, milk, or water tanks for level measurements or liquid level control.

- This sensor is useful in beam detection for high-speed counting.

- The robot sensor uses this sensor for robot sensing.

- The car parking systems use this sensor. Where the control of car entry is through a barrier system, the barrier must not be lower when there is a vehicle beneath it. The ultrasonic sensor controls this whole process.

- This sensor is useful in bottle-cutting and drink-filling machines. Where the bottles require detection at several points, we can use an ultrasonic sensor for continuous monitoring.

- This sensor is also useful in the transport of printed circuit boards (PCBs). In the industry where the designing, printing, and manufacturing of smart phones, computer motherboards, and home appliances occur.

- This car manufacturing industry also uses this sensor to manufacture or assemble the car automatically.

- This sensor is helpful in the car washing system for detecting and washing the car automatically.

- This sensor can detect the speed of a motor or generator.

- This sensor’s uses also include presence detection systems.

Advantages of Ultrasonic Sensor

- The ultrasonic sensor has high frequency, high sensitivity, and high penetrating power; therefore, it can easily detect external or deep objects.

- These sensors easily interface with a microcontroller or any type of controller.

- These sensors have greater accuracy than other methods for measuring the thickness and depth of a parallel surface.

- These sensors could easily sense the nature, shape, and orientation of specific objects that are within their area.

- The sensors are easy to use and not dangerous during operation for nearby objects, people, equipment, or materials.

Disadvantages of Ultrasonic Sensor

- During the use of an ultrasonic tester for testing, it is very important to know the operational manual; in other words, it requires careful attention from an experienced technician.

- During the development inspection procedure of equipment using an ultrasonic tester, testing technicians require extensive knowledge.

- These sensors are useful for inspection purposes, but they should be water-resistive; otherwise, they could get damaged.

- When these sensors are interfaced with a microcontroller or any controller, an experienced person or programmer is required.

Conclusion

In conclusion, this tutorial provides an in-depth overview of ultrasonic sensors and its types. It also covers the working principle, circuit diagram along with applications, advantages and disadvantages of ultrasonic sensor to help us better understand the concept. Hopefully this was helpful in expanding your knowledge.

You may also like to read:

- HC-SR04 Ultrasonic Sensor Interfacing with Arduino – Distance Measurement Example

- BME680 with ESP32 using Arduino IDE (Gas, Pressure, Temperature, Humidity)

- Arduino Rosserial Publish Range HC-SR04 Ultrasonic Readings to ROS

- HC-SR04 Ultrasonic Sensor with STM32 Blue Pill using STM32CubeIDE

- HC-SR04 Ultrasonic Sensor with Raspberry Pi Pico using MicroPython

- STM32F4 Discovery Board introduction : tutorial 1

This concludes today’s article. If you face any issues or difficulties, let us know in the comment section below.

I am working with Ultrasonic devices since last 40 years, In marine (Ship) this device call Echo sounder, Depth indicator , Fish finder & SONAR to measure the depth of sea, to detect mines , Submarine, Fish finding & many more, At Hospital Ultra sounds.

I like this subject by MR BILLAL.

Mr. Billal is a guru in this field. I enjoy reading his articles a lot because it enriches my knowledge.

Thanks Billal for yet another master piece.

thanks for your compliment

nice site